Effective Ways to Understand the Function of Tapered Roller Bearings

Understanding the function of tapered roller bearings is essential for anyone involved in engineering, automotive, or machinery fields.

These unique components play a pivotal role in reducing friction and supporting loads, making them crucial for the efficient operation of various mechanical systems.

By exploring their design, function, and applications, you can gain valuable insights into their significance in everyday machinery.

So, please continue reading to uncover effective ways to understand these fascinating bearings!

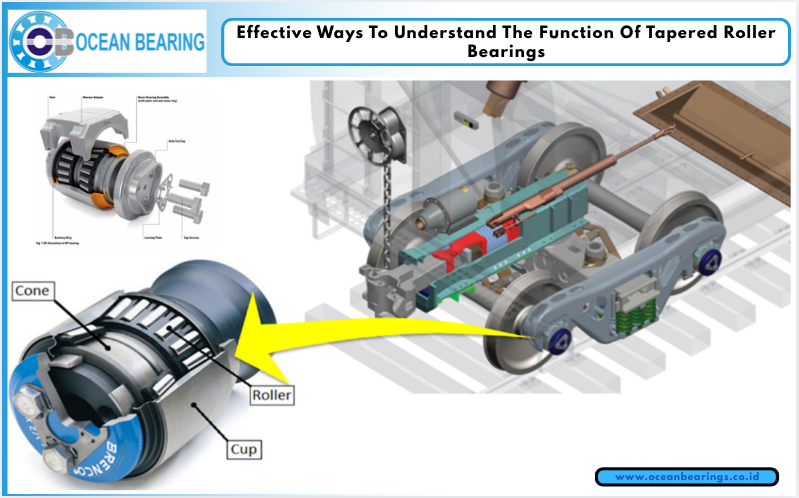

How Tapered Roller Bearings Work in Machinery

Tapered roller bearings play a crucial role in machinery by efficiently supporting both radial and axial loads.

Their unique design features conical rollers that allow for smooth rotation while minimizing friction.

This innovative structure enables the bearing to handle heavy loads without compromising performance, making it ideal for applications in automotive, aerospace, and industrial equipment.

As the inner and outer rings are tapered, the contact points are aligned in a way that enhances stability, ensuring smoother operation even under extreme conditions.

Additionally, the ability to adjust the clearance between the rollers and raceways allows for optimal performance and longevity.

By redistributing forces and reducing wear, tapered roller bearings not only improve efficiency but also extend the lifespan of machinery, making them an essential component in modern engineering.

Also Read: Effective Ways to Understand SKF Bearing Catalog PDF

Types of Tapered Roller Bearings and Their Applications

Tapered roller bearings are essential components in various mechanical applications, designed to handle both radial and axial loads.

There are several types, including single-row, double-row, and four-row tapered roller bearings.

Single-row bearings are commonly used in automotive wheel hubs for their ability to accommodate high loads with minimal friction.

Double-row bearings, on the other hand, are often utilized in industrial machinery where space is limited and the load demands are higher.

Four-row tapered roller bearings are typically found in heavy equipment, such as mining and construction vehicles, owing to their robust design and capacity for extreme loads.

These bearings are vital in ensuring smooth operation and longevity in machinery, making them indispensable in manufacturing, transportation, and heavy-duty applications.

Key Features of Tapered Roller Bearings Explained

Tapered roller bearings are essential components in various machinery, known for their ability to support both radial and axial loads.

One of their key features is the conical shape of the rollers, which allows for a larger contact area between the roller and the raceway, enhancing load distribution and overall performance.

Additionally, these bearings facilitate smooth rotational movement due to reduced friction, making them ideal for high-speed applications.

Their design also permits easy adjustment of the axial clearance, ensuring optimal performance under varying load conditions.

Moreover, tapered roller bearings are versatile and can be found in diverse industries, from automotive to aerospace, highlighting their importance in modern engineering.

Factors Influencing Tapered Roller Bearing Performance

Tapered roller bearings play a crucial role in various mechanical applications, and their performance is influenced by several factors.

One significant aspect is the design geometry, which affects load distribution and contact angles, ultimately impacting efficiency and durability.

Additionally, the material selection is vital; high-quality steel or advanced composites enhance wear resistance and reduce friction.

Lubrication also plays a pivotal role in performance; proper lubricant type and application ensure optimal operation and prevent overheating.

Furthermore, environmental conditions, such as temperature and humidity, can affect bearing life and functionality.

Regular maintenance and correct installation practices are essential to maximize performance and reliability.

Understanding these factors allows engineers to select the right tapered roller bearings for specific applications, ensuring longevity and efficiency in machinery operations.

Common Issues with Tapered Roller Bearings and Solutions

Tapered roller bearings are essential components in machinery, but they often encounter several common issues.

One frequent problem is improper installation, which may lead to excessive wear or premature failure.

To address this, ensure proper alignment and follow manufacturer specifications during installation.

Another issue is inadequate lubrication, which can cause overheating and damage.

Regularly check lubrication levels and apply the correct type of lubricant.

Additionally, contamination from dirt or debris can impact performance; therefore, using seals or shields can help maintain cleanliness.

Lastly, overloading the bearings may result in deformation and reduced lifespan, so it's crucial to adhere to load ratings and design parameters.

By understanding these issues and implementing appropriate solutions, the reliability and efficiency of tapered roller bearings can be significantly improved.

Maintenance Tips for Tapered Roller Bearings Longevity

Tapered roller bearings play a crucial role in various machinery, and maintaining them is essential for longevity and performance.

Regular lubrication is vital; using the correct type and amount of lubricant reduces wear and prevents overheating.

It's also important to monitor operating temperatures and vibrations, as fluctuations can indicate issues that need addressing.

Ensure proper alignment during installation, as misalignment can lead to premature failure.

Regularly inspect the bearings for signs of wear or damage, such as pitting or discoloration, and replace them if necessary.

Additionally, maintaining a clean environment around the bearings helps prevent contamination, which can significantly affect their lifespan.

By following these maintenance tips, you can enhance the durability and efficiency of tapered roller bearings, ensuring they function optimally over time.

Benefits of Using Tapered Roller Bearings in Engineering

Tapered roller bearings offer several advantages in engineering applications, making them a popular choice in various industries.

Their unique design allows them to accommodate both radial and axial loads, providing enhanced stability and performance.

This versatility results in improved efficiency and reduced wear on machinery, leading to longer service life.

Additionally, tapered roller bearings have a higher load-carrying capacity compared to other bearing types, which is essential for heavy-duty applications.

Their ability to handle misalignment also contributes to smoother operation and less vibration, further enhancing reliability.

Moreover, these bearings facilitate easier installation and maintenance due to their straightforward design.

Overall, the benefits of using tapered roller bearings contribute significantly to the efficiency and longevity of engineering systems, making them an essential component in modern machinery.

Comparative Analysis: Tapered vs. Other Roller Bearings

Tapered roller bearings are distinct in their design and functionality compared to other roller bearings, such as cylindrical and spherical types.

They feature an inner and outer race that taper towards each other, allowing them to handle both radial and axial loads efficiently.

This unique geometry enables tapered bearings to provide better load distribution, reducing stress and enhancing performance under heavy loads.

In contrast, cylindrical roller bearings excel in high-speed applications but are limited in axial load capabilities.

Spherical roller bearings, while accommodating misalignment, may not offer the same precision as tapered designs.

Consequently, tapered roller bearings are often preferred in applications where both load capacity and alignment are critical, making them a versatile choice in various industrial settings.

Overall, the comparative analysis reveals that the specific requirements of an application will dictate the suitability of tapered roller bearings versus their counterparts.

Installation Techniques for Tapered Roller Bearings

Tapered roller bearings are essential components in various machinery, ensuring smooth rotation and load distribution.

The installation of these bearings requires precision and care to achieve optimal performance.

First, it is crucial to clean all surfaces to prevent contamination.

Next, apply a suitable lubricant to facilitate smooth operation.

When positioning the inner and outer races, ensure that the tapered surfaces align perfectly to avoid misalignment, which can lead to premature wear.

Utilizing a hydraulic press can help achieve the necessary interference fit, reducing the risk of damage during installation.

After securing the bearing, it’s vital to check for proper clearance and adjustment, as this affects overall functionality and longevity.

Following these techniques ensures that tapered roller bearings operate efficiently, enhancing the reliability of the machinery they support.

The Role of Lubrication in Tapered Roller Bearings

Lubrication plays a crucial role in the performance and longevity of tapered roller bearings.

It reduces friction between the moving parts, minimizing wear and tear.

Proper lubrication ensures that the bearings operate smoothly under various load conditions, enhancing their efficiency.

It also aids in heat dissipation, preventing overheating that can lead to premature failure.

The choice of lubricant, whether oil or grease, significantly impacts the bearing's ability to perform in different environments.

By maintaining an optimal lubrication level, users can prolong the lifespan of the bearings, reduce maintenance costs, and ensure reliable machinery operation.

Regular monitoring and timely reapplication of lubricant are essential practices for maintaining the functionality and reliability of tapered roller bearings in various applications.

To Wrap Up

In conclusion, understanding the function of tapered roller bearings is essential for enhancing performance and longevity in various applications.

By recognizing their unique design and operational characteristics, you can make informed decisions that contribute to greater efficiency and reliability.

We hope this article has provided valuable insights into this crucial component.

Thank you for reading, and don't forget to share this interesting article with your friends!

.png)

✦ Tanya AI